APPLICATIONS

EDXRF is used in a wide range of applications, from the electronics industries in measuring plating thickness, to the jewelry industry for elemental compositional analysis of precious metals. Most often application support is best provided through direct contact via phone or email. When contacting us for the support it is helpful if you are able to provide the following information:

| XRF sample presentation for accurate and precise analysis

The sample should be optically flat and well mixed if it is a powder or solution If these two criteria are met EDXRF can readily be used to measure elements Na(11) through U(92), from sub-ppm to % levels

|

|

|

|

|

|

Industries

- Metal Manufacturers

- Metal Fabricators

- Petroleum Pipelines

- Metal Welding

- Scrap Dealers

- Smelters

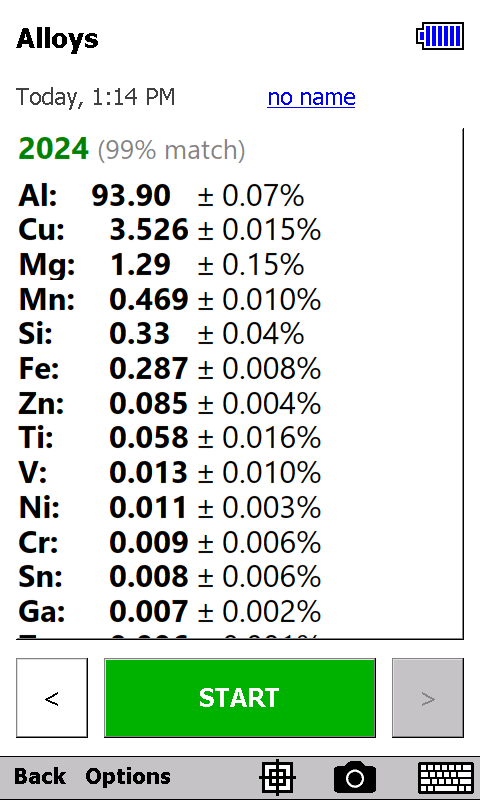

X-ray spectrometer analysis will detect and identify all steels, as well as the following alloy bases:

- Aluminum

- Magnesium

- Titanium

- Cobalt

- Nickel

- Copper

- Zinc

- Precious metals

- Rare-Earth metals

- Niobium

- Lead

- Zinc

- Tin

Applications

- Alloy identification

- Grade sorting

- Hazardous Material Identification

- Corrosion Inspection

- Weld quality

Industries

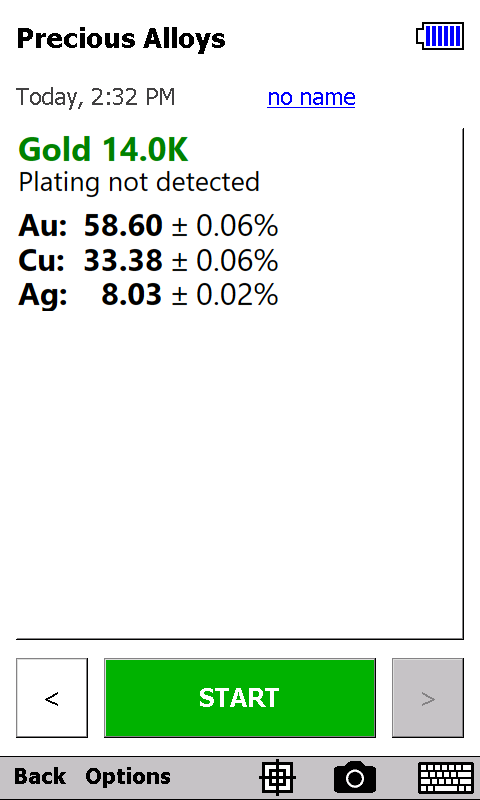

- Manufacturing Jewelers

- Precious Metal Suppliers

- Precious Metal Traders

Nowadays, XRF technology is the best solution to determine the full composition of any precious metal. The advantages are plenty and resolving most of the issues of the old analysis methods:

Applications

- Karat Rating

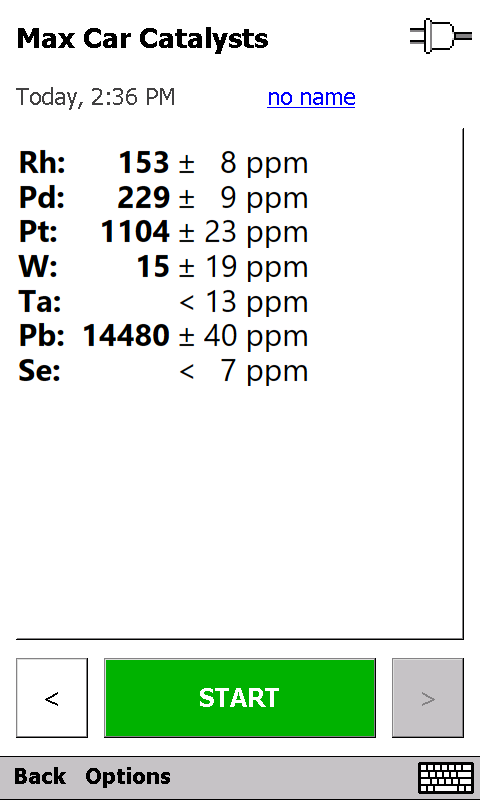

- Precious Metal Content of Auto Catalysts

- Plating Analysis

- Non-conventional Alloy identification

Industries

- Electronic Waste recyclers

- Electronic component manufacturers

- Regulatory authorities

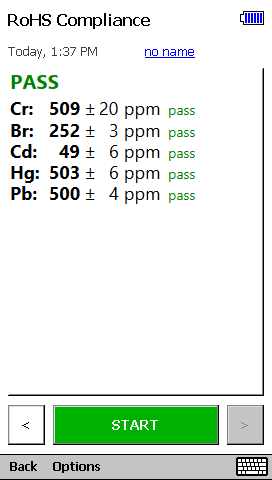

What is RoHS?

Applications

The RoHS Directive, also known as Directive 2002/95/EC, entered into effect on July 1, 2006. The directive restricted the use of six chemicals harmful to human and environmental health in electrical and electronic equipment (EEE). ROHS 2 added another class of chemicals – phthalates

These six chemicals and their accepted thresholds

- Lead (Pb), (≤ 0.1%)

- Mercury (Hg), (≤ 0.1%)

- Cadmium (Cd), (≤ 0.01%)

- Hexavalent chromium (chromium VI, Cr+6), (≤ 0.1%)

- Polybrominated biphenyls (PBB), (≤ 0.1%)

- Polybrominated diphenylethers (PBDE), (≤ 0.1%)

XRF analysis is one of the most effective methods to solve this problem.

Industries

- Refineries

- Pipeline Companies

- Storage Facilities

- Testing Labs

- Lubricating Oil Producers

- Re-refiners

Applications

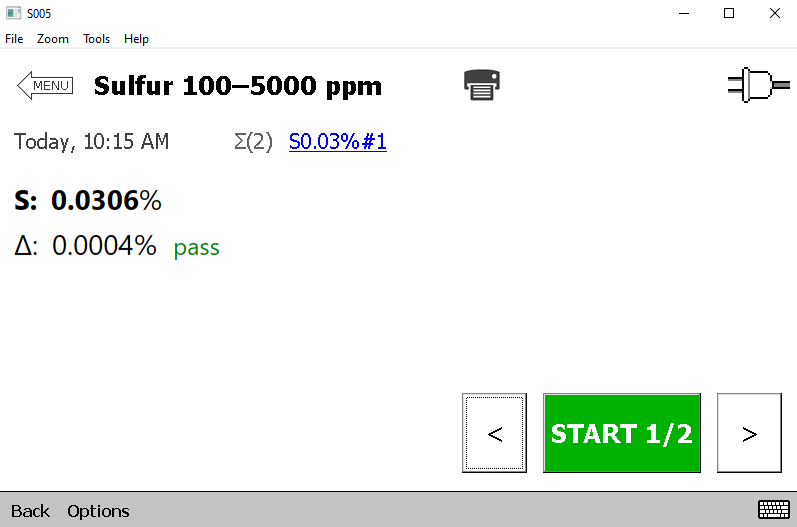

- Analysis of sulfur in oil and petroleum products, such as gasoline, diesel fuel, motor and transmission oils

- ASTM D4294, ISO 20847, IP 496

- S from 2ppm – 5wt%

Industries

- Mine Exploration

- Minesite Operations

- Flotation Plants

The capability of precise analysis of light elements is very important for understanding sample mineralogy, and it is critical for the analysis of certain types of minerals such as bauxite and limestone. During exploration, handheld XRF analyzers are good for fast screening of vast areas due to the light weight and mobility of the instrument.

Applications

- Geo Mapping

- Ore Grade Analysis

- Feed and Tails Metallurgical Balance

- Smelting

- Refining

You Can Quickly Determine Gold Concentration in various forms

It doesn’t matter in what format the gold is in your hands. Portable XRF analyzer for gold can scan:

- Gold bullion

- Gold ore

- Jewelry

It is convenient and progressive since you do not need to worry about the shape of a gold piece to analyze it. A portable gun can do this in any format.

Institutions

- Museums

- University Archaeology Departments

- Art Insitutes

Applications

- Art authentication

- Archaeology Digs for artifact classification

- Education for Art restoration

Download App note

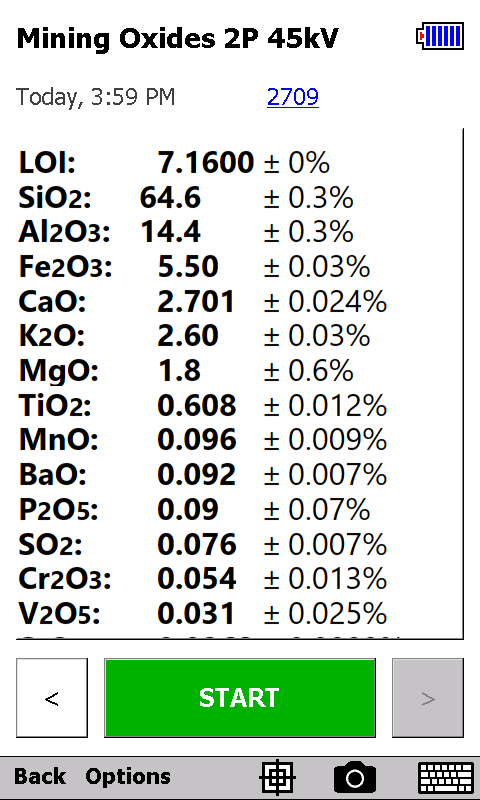

Industries

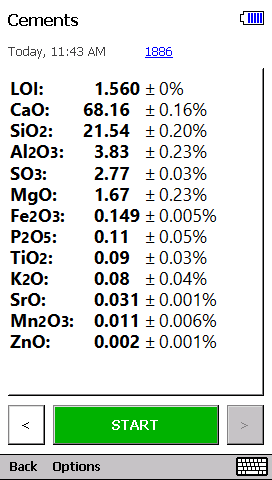

- Cement Manufacturers

- Building Contractors

- Site Remediation Companies

- Specialty building products

Cement is a binder substance. If rocks or gravel and cement mixed with water, the solution begins hardening and afterwards making concrete. Due water-cement mixing, SiO 2, CaO, Fe 2O 3, and Al 2O 3 are hydrated to form ferrite of aluminium hydrate and calcium silicates of aluminium, cement ability to assert as a result.

Cement production mainly uses low-melting clays, argillites and shales, which are part of the cement mixture. The second main component is carbonate rocks. Limestone and clay are the raw material for cement production. They are mixed in a certain ratio (75-80% limestone and 20-25% clay).

Applications

- Oxide Analysis

- Elemental Composition

- Impurity Identification

- HAZMAT material identification